Custom Packaging

EcoRich Industrial leverages its extensive experience and continuously adopts new automated equipment and learns emerging technologies. We provide diverse packaging services for manufacturers and customers, offering various container options such as needles, metal containers, plastic canisters, and customized packaging to meet the specific needs of different chemical products.

Packaging process

If you require contract manufacturing and formulation services, you can fill out the inquiry form or send an email . We will arrange for a technician to discuss your requirements with you. After confirming the details, we will conduct sample testing and provide a quotation. Waste generated during the contract manufacturing process will be handled by qualified “Class A” waste removal services. Before leaving the factory, quality inspections will be conducted, and environmentally friendly packaging materials will be prioritized.

Requirements Discussion

Sample Test

Quote Confirmation

Filling and Packaging process

Appoint Grade A of the clearance of waste

Inspection report

Packaging and shipping

low-carbon materials

Container type

We offer a variety of packaging containers for selection, including dual-component dispensing tubes, containers for UV adhesives, EDF dispensing syringes, disposable small packaging bags, etc. Each style comes in different capacities. If you are unsure which one to choose, we can provide professional advice to assist you in selecting the appropriate container for your needs.

Packaging Equipment

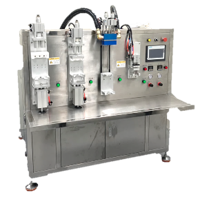

Two-part filling machine

Designed for dual-component dispensing of adhesive materials through syringes, it allows precise filling for various ratios such as 1:1 or 2:1.

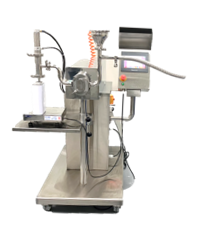

Liquid filling machine

Applicable for solvent materials, it utilizes an electronic scale to calculate the filling quantity, ensuring a consistently stable dispensing amount for each batch of products.

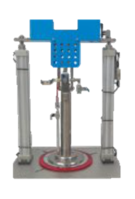

1L/20L plate pump system

Primarily used in conjunction with automated filling machines, it facilitates the feeding system for high-viscosity materials. It is suitable for high-viscosity substances such as silicone gel and epoxy resin.

OEM Equipment

Four-axis planetary mixer

Utilizing a planetary-style self-rotating stirring structure, it thoroughly mixes the material formula, suitable for substances like silicone gel and epoxy resin.

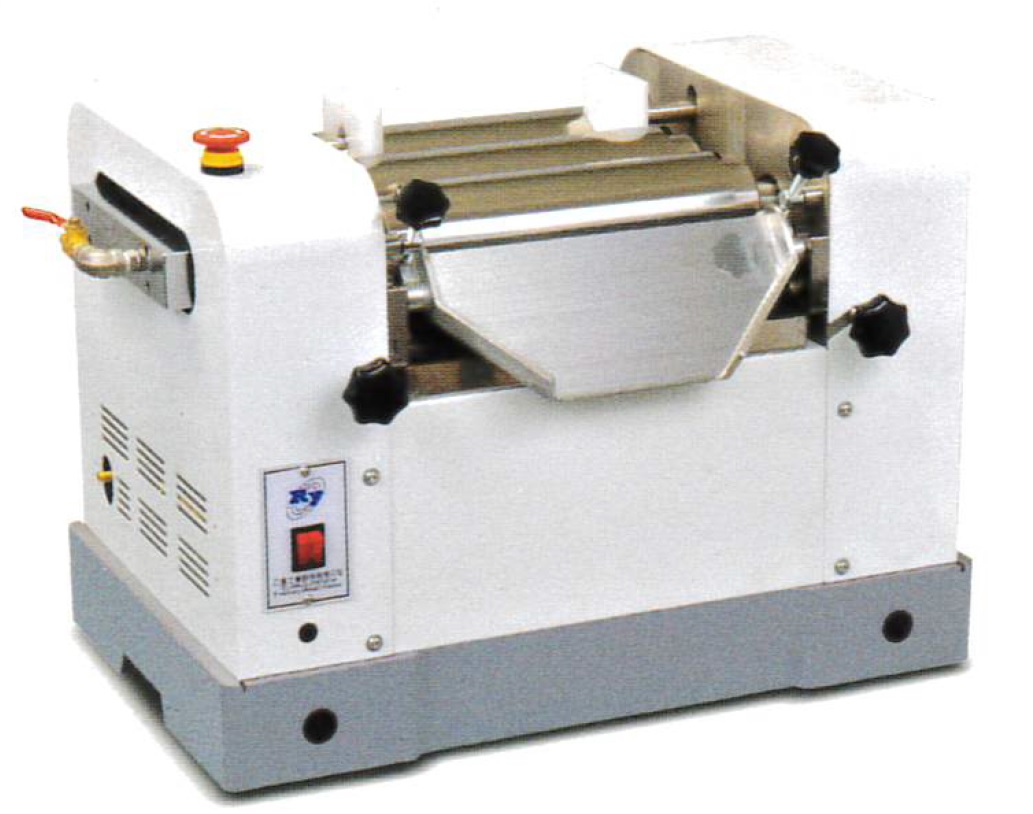

Triple roll mill machine

By utilizing different speeds between the rollers, this method uniformly disperses material formulas, making it suitable for viscous liquids.

Production Environment

Yellow light production room

For UV-curing products, a yellow-light production room is employed to prevent premature curing reactions of the adhesive material during the production process.

Clean production room

In limited space, control pollutants (airborne particulates, airborne microorganisms, and chemicals) within specified limits.

繁體中文

繁體中文